Product

Trough Cable Tray Machine for Electrical Projects

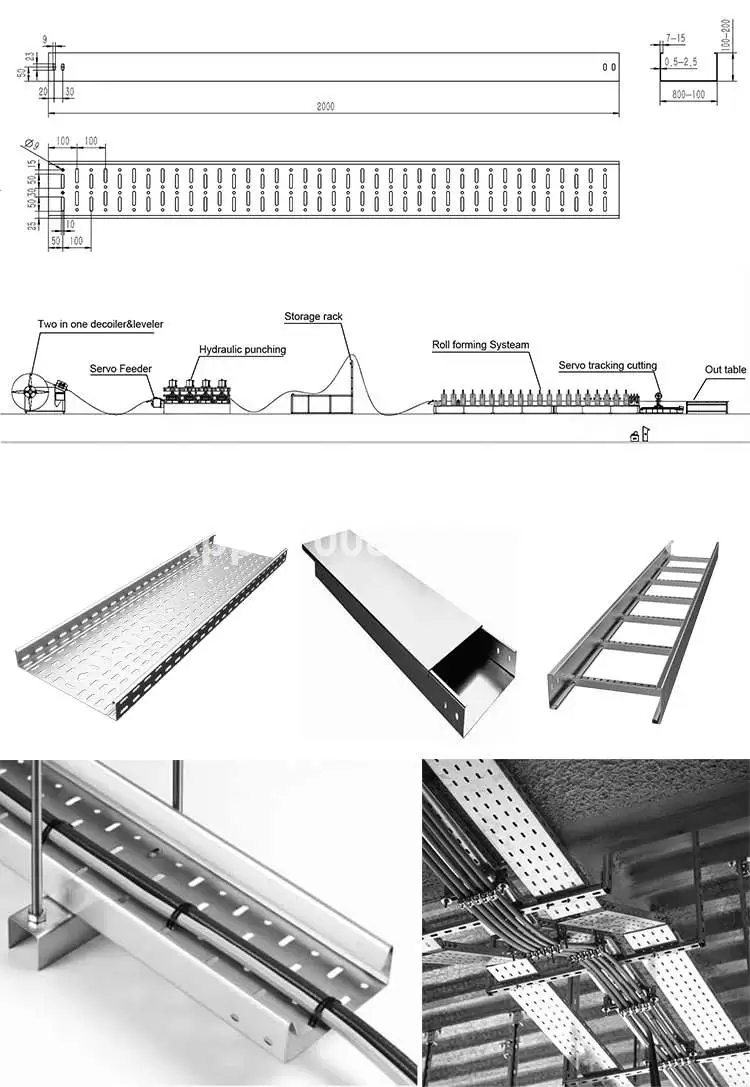

The trough cable tray machine is a specialized production line for manufacturing trough-type cable trays used in electrical wiring systems. This machine integrates roll forming, punching, and cutting into a fully automatic process, ensuring high precision and consistent quality.

Made with robust steel rollers and equipped with an advanced PLC control system, the machine delivers reliable performance and stable operation. It can produce trough cable trays of various sizes, thicknesses, and designs, meeting the needs of diverse electrical projects.

The trough cable tray machine is widely applied in factories, commercial buildings, power plants, and infrastructure projects. It provides advantages such as high productivity, reduced labor cost, and long service life. With customizable configurations, it offers manufacturers and contractors an efficient solution for producing strong and durable cable tray systems.

Contact us for a quote on cable tray machines!

Trough Cable Tray Machine for Electrical Projects TFCHNICAL PARAMETEF

| Model parameters | 800/200 |

| Equipment footprint | 36*2.5*2(L*W*H)m |

| Rolling strip width | 200-1250mm |

| Rolling strip thickness | 0.5-2.5mm |

| Product specifications | 800/200-100/50 |

| Total installed capacity of equipment | About 60KW |

| Rolling strip material | Q235 cold-rolled strip steel,galvanized sheet |

| Online punching and production speed | 6-10 meters/minute including punching connection holes (determined by product length and punching quantity,excluding punching tray holes) |

| Rolling workpiece length | 2000mm/3000mm |

| Explosion proof grade of motor | ExdlICT4 |

| Motor protection level | IP55 |

Contact us for a quote on cable tray machines!

Other related machines

1.Trough Cable tray machine

2.Cable tray cover machine

3.Ladder type cable tray machine

4.Cable tray bending machine

Our Philosophy

Providing Innovative Roll forming Machine Solution

We Use Advance Manufacturing Process

Provide Unique Technology

Group Of Certified & Experienced Team

Why Choose Us

28 + Yeas Professional Experience

9000 + ㎡ Factory Area

5 + Core Product Lines

100% Customized Solutions